DotLine GmbH

Bielefeld

DotLine GmbH develops and manufactures CTP systems as well as electronic, mechanical, and optical components for technical applications. For over 20 years, we have supported companies with engineering services,

prototyping, and IT expertise.

_

Optical Systems

The development of optical systems for industrial and technical applications – including laser optics, beam guidance, image processing, and precision positioning systems – is part of our service portfolio. Design, simulation, and integration are carried out in-house, often in close coordination with mechanics, electronics, and software.

_

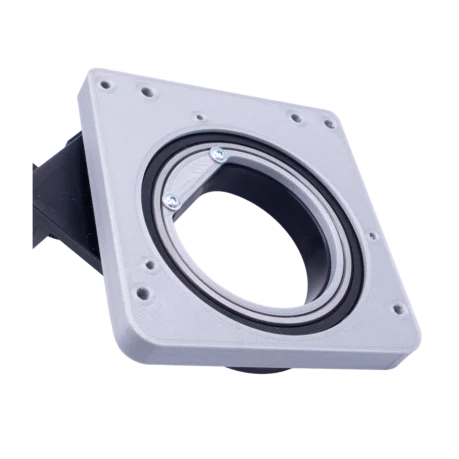

Mechanical Engineering

We design mechanical components and assemblies – from precision parts and sheet metal to milled parts and complete housings. Our design work is done using 3D CAD and is closely coordinated with electronics, optics, and software. We focus on functionality, manufacturability, and seamless integration into existing systems.

_

Electronics Development

Electronic assemblies are developed in-house, from circuit design and PCB layout to complete control systems – including firmware and commissioning. Our scope covers sensor and actuator systems, power electronics, and FPGA-based solutions. We focus on durability, robustness, and seamless integration with mechanics and software.

Computer To Plate

_

SMAX

Compact CTP system for smaller print runs or as a backup unit. The SMAX offers automatic loading, variable resolution, and full integration into existing workflows – all with minimal space requirements.

_

VMAX

High-performance CTP system for high volumes and short production times. The VMAX processes up to 400 plates per hour and supports various formats in fully automated operation.

_

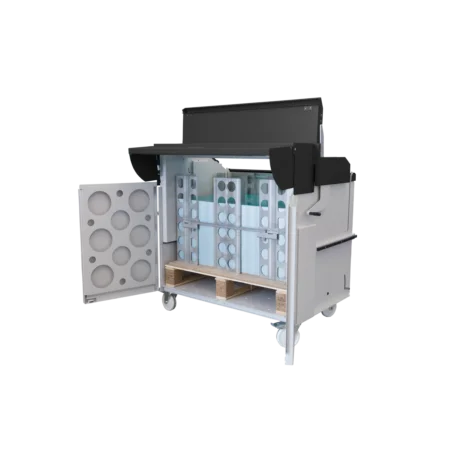

Palette-Loading

Pallet loader for maximum autonomy: up to 6000 printing plates readily available, quick cassette changes, and combined operation with standard and pallet cassettes – for uninterrupted CTP production.

3D-Printing

3D printing is an integral part of our development and manufacturing workflows. It allows us to respond quickly, flexibly, and cost-effectively to the needs of prototyping and small-scale production.

_

Design

Parts for 3D printing are created directly from our CAD designs – tailored to function, manufacturing method, and installation requirements. Geometry, material selection, and printing strategy are already considered during the development phase.

_

Printing

We produce functional prototypes, brackets, and housing parts using FDM and SLA processes – depending on requirements, robust, high-resolution, or heat-resistant. Printing is carried out in-house with short turnaround times.

_

Finishing

Printed parts are refined as needed by sanding, drilling, coating, or combining them with threaded inserts, adhesives, or other components. This results in ready-to-assemble functional parts and precise prototypes.